Help to remove most historical problems

Un-pickled Patch l Oxide l Carbon Suit l Oil Patch l Black Spots l Rusty Surface l Mill Scale l Scratch l Rolled in Scale

Our Field trial has proved that saving on pickling chemical cost reduction to the tune of 70% to 75% can easily be obtained by reducing concentration of chemical.

Features:

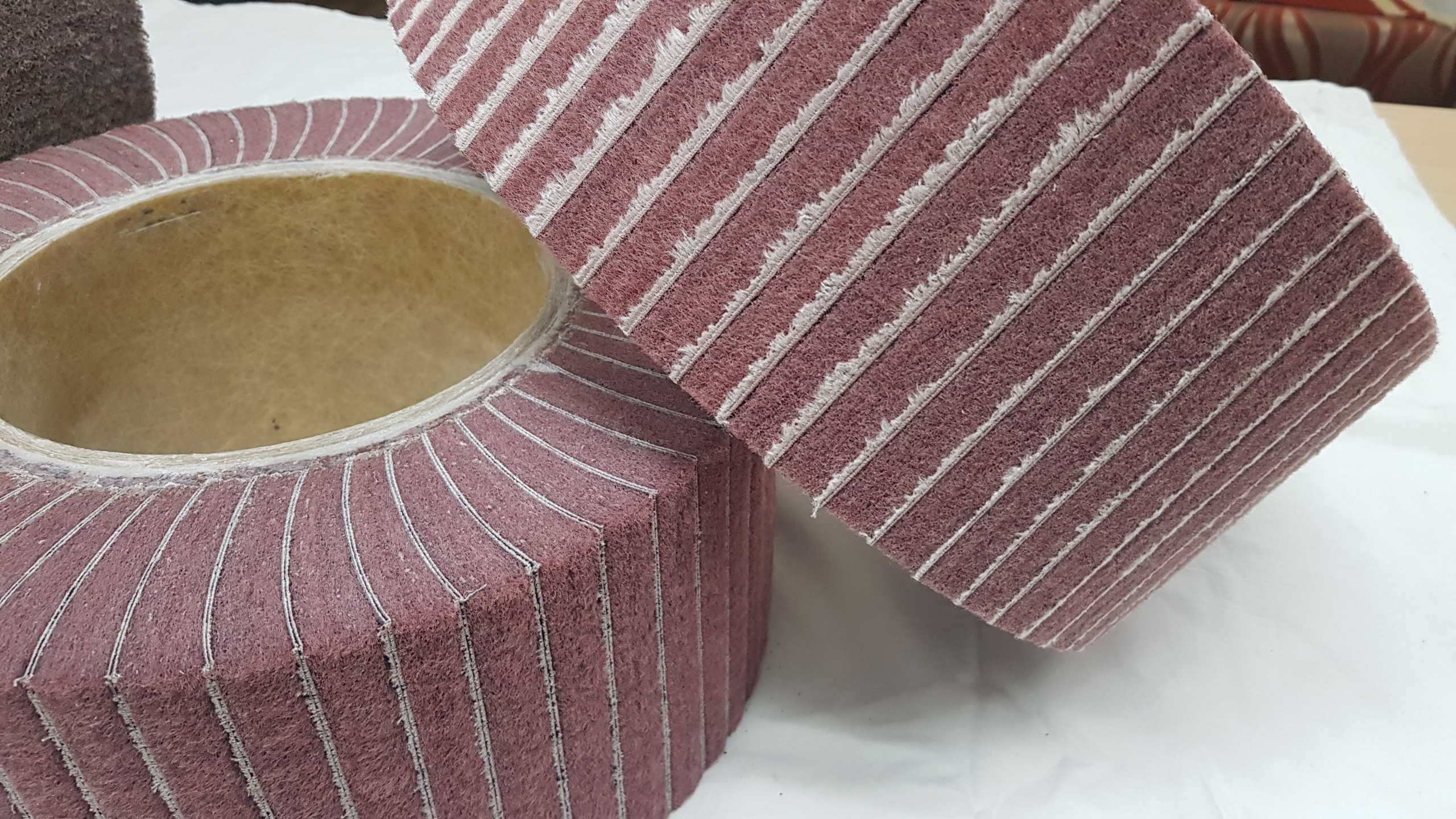

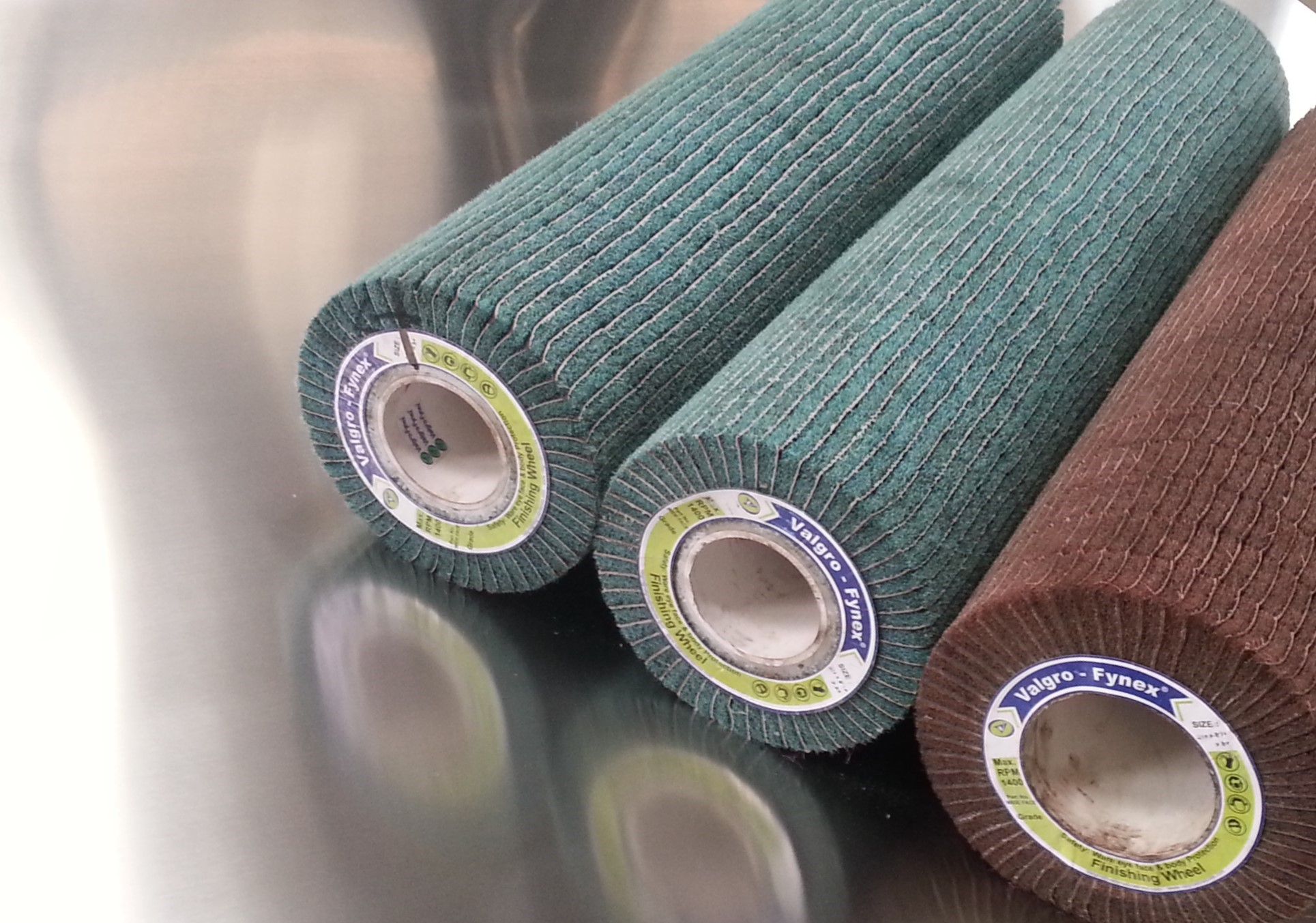

- Discs are resin bonded together on a circular core for increased durability

- Brushes are built around a steel / FRP core, resisting deflection under heavy pressure

- Made with aluminum oxide mineral or silicon carbide for sharp cutting action

- Open web resists loading, contributing to longer abrasive service life

- Open web responds to surface irregularities without altering geometry of the part

Benefits :

- Effective removal of corrosion, burrs, dirt.

- Decorative, even surface finish with a defined roughness depth, e.g. stainless steel, copper and brass.

- brushes are a good match for cleaning flat surfaces, because they will smooth surface irregularities without sacrificing the geometry of the part.

- The open web resists loading by limiting clogging of the fibers. This keeps the mineral cutting sharper longer.

- We recommend using a lubricant or coolant when cleaning. It assists in washing away swarf and reduces loading, which helps extend the brush’s service life.

Technical Specification

Available Size OD: 300mm, 350mm, 400mm, 450mm, 500mm Width: 400mm to 2500mm Grade: CRS, MED, FN, VFN, SFN, NFN Special Size can be available on request.

- Typical applications for VALGRO cleaning brushes include coil cleaning prior to coating, deburring, scale and oxide removal and reclaiming sheet and coil.

- It’s a good option for operators looking for optimum flexibility and an aggressive cut.

- IF YOUR LOOKING FOR THE BEST BRUSH TO OPTIMIZE YOUR SPECIFIC APPLICATION, YOU SHOULD CALL US!