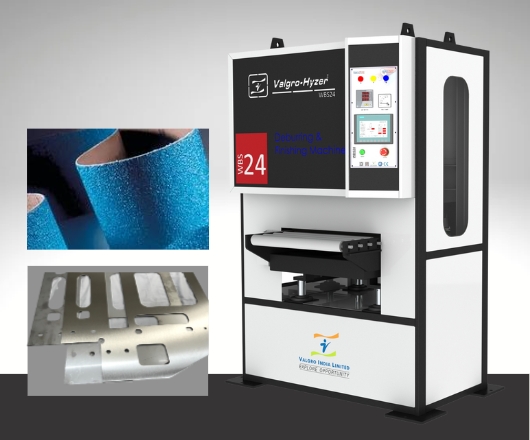

Valgro NON-WOVEN ABRASIVE SURFACE CONDITIONING

CLEANING – FINISHING – DEBURRING – DEOXIDIZING – DESCALING

The principle reason to select the Valgro-Fynex non-woven material, is for the purpose of achieving the desired result, with a uniform satin finish.

Valgro Non-Woven brushes bring the maximum amount of abrasive grit points in contact with the surface.

IF YOUR LOOKING FOR THE BEST BRUSH TO OPTIMIZE YOUR SPECIFIC APPLICATION, YOU SHOULD CALL US!

ADVANTAGES

- Do not alter geometric shape of work piece

- Increase surface resistance against corrosion

- Enlarge the surface, resulting in optimal adhesive qualities for subsequent coatings

- Equal distribution of abrasives guarantees a uniform and reproducible surface

- Used in dry or wet conditions and in connection with oils and/or mild detergents

- Cause minimal heat to the work piece

- Facilitate easy profiling

- Ready to use at any time—no long assembly times involved

- Do not get glazed over as other media

- Operate at low noise levels

- Do not require secondary devices for deburring

CHARACTERISTICS

- Excellent self-healing performance under surface tears

- long life – Cool running

- Various Grit sizes and finishes

- Impregnated Non-Woven nylon brushes for special applications

- Dynamically Balanced

- Industries Largest Selection of Valgro Non-Woven Abrasive Materials