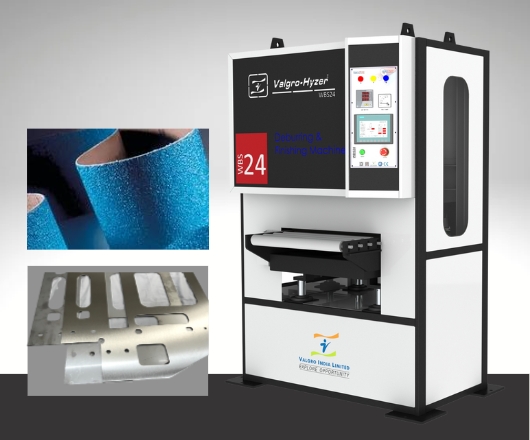

Valgro Plate Polishing machine features and principles

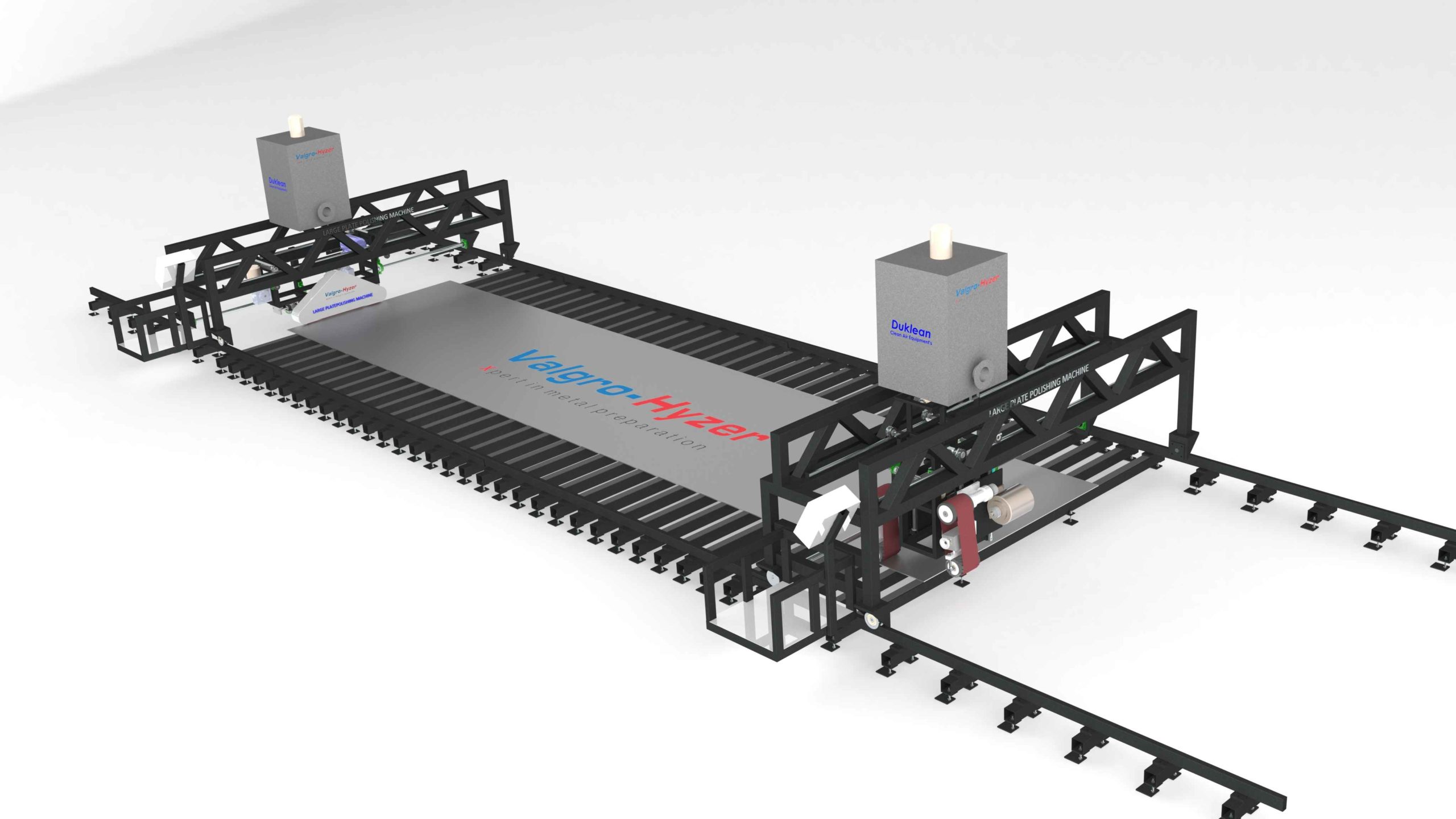

Valgro Large and Thick Plate Polishing machine – Features.

The efficiency of equipment is an important factor in deciding a Machine. Most equipment performs at efficiencies much below their rate due to various losses associated with it. A Plate Polishing Machine works at an efficiency 6 Times that of Domestic Equipment. The Stainless-Steel Hotplate can attain a finish of 4K. This machine accommodates Plate sizes up to 5 Meter Width & 13 Meter Length & can take up Weights (Loads) of up to 110 Tons.

Working principle of Polishing machine

The key to the operation of the polishing machine is to remove the damaged layer as soon as possible and to get the maximum polishing rate & finish.

The Coarser abrasives ensure a greater rate of Polishing & greater coverage of damaged surface areas. While the Finer abrasives ensure desired polish finish but at a lower rate.

Understanding the defects & fine-tuning the Polishing process is the key to better results.

The polishing machine is specially designed for the surface treatment of steel, aluminium copper and other metal products and pipes. Dozens of original accessories meet different needs. It can easily produce snow patterns, brushed patterns, wave patterns, and matte surfaces with different precision, Mirror surface, etc.,

This machine quickly repairs light or deep scratches, welds, nozzle marks, traces of oxide film, stains and paint, etc.

This machine is suitable for deburring, forming rounded corners, decorative metal processing, in No shadow, transition zone and the uneven decorative surface will be formed during processing, which is an important equipment of metal product production line.